Pill 7 - MES Software and Industry 4.0

Let's talk about MES: their aim is to highlight the stops in order to subsequently define the reasons for them and make the company prepare an improvement.

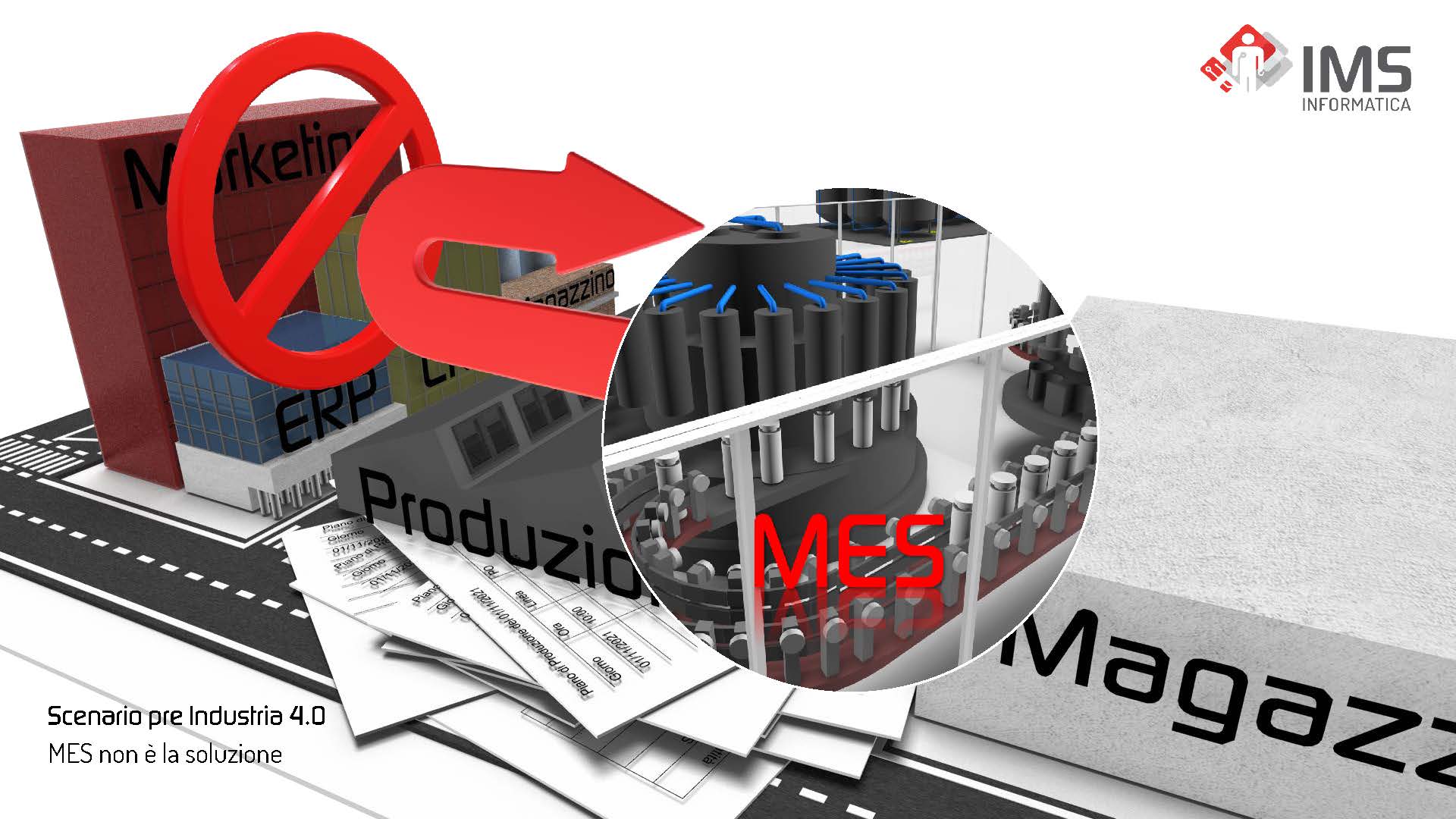

An MES is needed when the production lines have an efficiency between 70% and 75% with average stops of 5 minutes. The 70% efficiency means that on 3 production shifts the line is stopped just over 7 hours, at lower levels it is useless to apply the ESM: the stops are evident! With the purchase of the ESM, the company must also be able to prepare new projects for the resolution of stops and bottlenecks! Knowing its own inefficiency, and not having the tools to solve it, makes the ESM useless and frustrates the investment. An ESM is therefore not an Industry 4.0 tool: the flow is from the machines to the company and not the other way around. Moreover, if you buy a label printer, a boxing machine, a filling machine, etc.. you will be provided with the relevant configuration software, but as they are not integrated they will move the possibility of error from production to a control room.

Can these configurators be financed?

Maybe, but the connection with the company systems must exclude the interoperability with the operator otherwise they are not.